A report about the installation of a cutting system in the Developer Diaries? You are probably wondering whether this is the right place for this blog post. But we at RG Technologies believe that practical experience is important for all employees to ensure optimal further development of our products. That's why I was involved in the installation of the system for our new customer Trendi Holdings in Durban as support for our Application Engineer Peter Unterseher.

Another reason was the scope of the installation. Setting up a cutting system, including all available modules, and the CAD is very difficult for one person to do in a fortnight. Especially when you consider that the client's team also has to be trained during this time, and that this was our very first installation in South Africa.

We needed the first few days to set up the Bullmer cutting table. Starting with the optimal position of the system up to the final implementation and first test cuts. At the same time, we were able to start attaching the mounts for the sensors and the projectors.

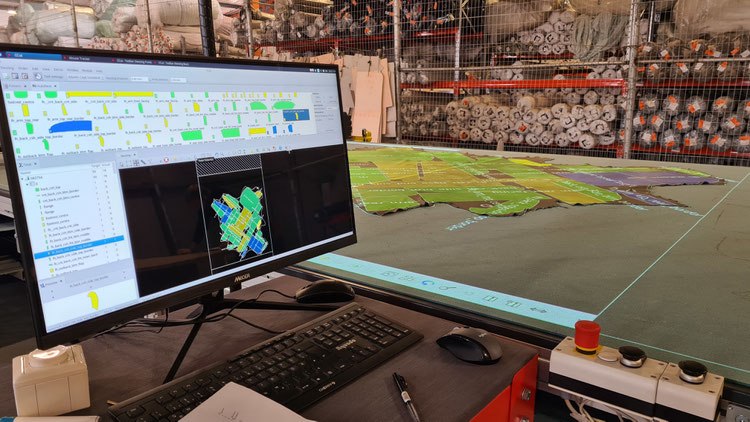

The following pictures already show the front work area where the leather skins are captured and the parts are nested. In the background, the hanging of the projectors for sorting of the parts after cutting is being prepared. After the first provisional cabling, the tests for the capturing and nesting could be started.

In the background of the two pictures you can still see the templates for manual cutting that have been used so far. The aim is to get this area completely free.

In the second week, training on the cutting table and CAD could begin as planned. On the second day of the training, parts designed in our system were already being cut for production. In the course of the week, the team became more and more independent and in the last days we were only on site for support and advice during production.

I would especially like to thank all the people involved from Trendi Holdings, N&T Sewing Technologies, Bullmer and Esto Schintex who actively supported us during the installation of the system. Without their help, the installation would not have been so straightforward and successful.

Derrick and Timm from N&T Sewing Technologies in particular looked after us during the entire two weeks, even apart from work, and introduced us to the hospitality of South Africa. We would also like to thank Jeremy Rom, the CEO of Trendi Holdings. We will be happy to come back.

Finally, to come back to the practical relevance: Yes, we have learnt a lot from this installation and will incorporate the new experiences into the further development of our products.

Stay online and best regards

Gerald Meister