PEAKTOURe 3D

A Development Project with the Gabor Shoes AG

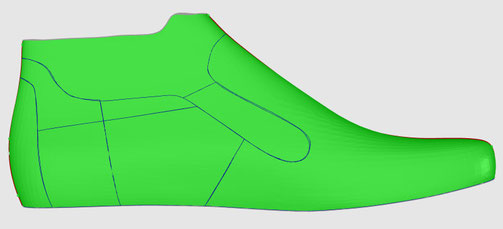

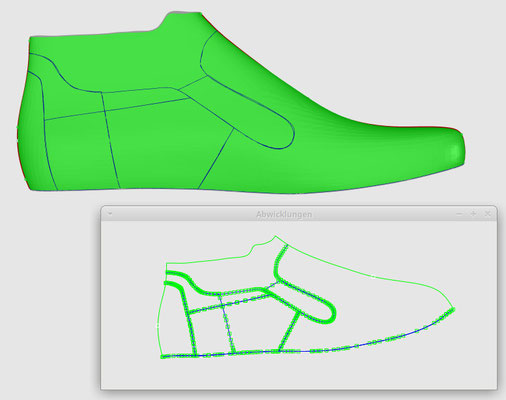

in 2018, Gabor Shoes AG approached us with the request to flatten 3D data and make it available in the CCAD 2D Design. The data includes the last and the belonging design lines. The application should be used in the technical model department to create digital last flattenings and basic models. The list of requirements for this project was extensive.

Requirements

The PEAKTOURe 3D project contained the following objectives:

- The 3D data in STL or OBJ format generated in 3D Schuhdesign and is exported there

- Import of last data including design lines into PEAKTOURe 3D

- Digitizing the design lines after the import on the last, in case they do not already exist

- Separating the last into inside and outside to flatten the two parts separately

- Further processing of design lines in PEAKTOURe 3D

- Flattening the two parts of the last and the design lines for further processing in the CCAD 2D Design

- Setting up an interface between the systems 3D Schuhdesign and PEAKTOURe 3D in both directions.

In addition to the technical needs a high value was set on:

- High accuracy of the flattenings

- Repeatability of the flattenings

- Quick and easy interaction

- Intuitive user interface

- Work supporting automatisms

- Flexible licensing via network

Is the Project Viable?

After careful consideration of the requirements, analysis of the data provided and several meetings of Gabor and RG Technologies, we considered the project to be viable. The effort and timeline were estimated. Our developers were able to start with their work.

In the course of development, we regularly met with Gabor's responsible employees to present the previous results. We received great approval from the very beginning. It became clear quickly: we are on the right track, the project is feasible.

Collaboration between RG Technologies and Gabor Shoes AG

The collaboration between the experts of Gabor and our team went smoothly and, as you can see in the results, was extremely productive. Together we moved forward progressively and within short time we were able to present first results. However, these also created new demands. Since Gabor's absolute priority is, to retain the extraordinary fit of their shoes, it was necessary to equate the digital flattening with the previous manual flattening. New algorithms had to be created to achieve this goal. All specific questions of our developers concerning the topic shoe and fit, were answered reliably and competently by the project team of Gabor. The development went hand in hand at all times.

Prototype of PEAKTOURe 3D

After the installation of the first prototype of PEAKTOURe 3D, the software solution was tested thoroughly. In order to meet the requirements of the variety of different lasts, adjustments in the algorithm were required. Ultimately, all cases were covered and optimal results achieved.

PEAKTOURe 3D in Series

So far, three licenses of PEAKTOURe 3D have been installed. Additional Systems are in planning. Each season about 35 new lasts are automatically flattened in the development department of Gabor Shoes AG in Rosenheim. With PEAKTOURe 3D results are achieved fast, precise and repeatable.

Additional Value through PEAKTOURe 3D

The flattening of last and design lines with PEAKTOURe 3D works extremely efficient compared to the previously used manual flattening. 2D data of the imported lasts and design lines is generated quickly and with the maximum accuracy. The result is reproducible at any time. Further processing in CCAD 2D Design happens without loss of flattening accuracy.

Feedback from Gabor Shoes AG on PEAKTOURe 3D

"We are very satisfied with PEAKTOURe 3D and the process of development of this software solution. All our requirements were met by RG Technologies. The collaboration between our internal experts and RG Technologies was excellent. The added value of the project is obvious: we achieve the desired efficiency and, above all, a consistent result. "

Heinrich Obweger

Head of Technical Model Department at Gabor Shoes AG

About Gabor Shoes AG

Gabor Shoes AG is a leading manufacturer of high-quality, fashionable women's shoes and is one of the big players in the shoe industry. Essential features of a Gabor shoe are fashionable topicality, extraordinary fit and high quality finish. The company has its headquarters in Rosenheim with more than 3000 employees in different locations in Europe. About 400 different models are developed per season. Gabor sells about 9 million pairs of shoes every year.

Das Team von RG Technologies freut sich auf Ihre Anfrage. Nehmen Sie am besten noch heute Kontakt mit uns auf.