Software Solutions, Production Technology and Services

RG Technologies is a developer and supplier of innovative and integrative software solutions, technologies and services. For many years we have been dealing with product development and production processes in the processing of leather and flat materials.

On our homepage you can inform yourself comprehensively about us. Please contact us for any questions.

RG Technologies Blog

Fakuma from 17. - 21. Oktober 2023

We have another trade fair coming up. Fakuma is the world's leading trade fair for industrial plastics processing, offering a comprehensive overview of all plastics technologies. We are pleased to be part of the nearly 1,500 exhibitors.

📅 When: October 17 to 21, 2023

🏢 Where: Friedrichshafen Exhibition Center

At the Rolf Schlicht booth, together with Aristo Cutting Solutions, we will present our latest technologies and solutions for automatic cutting. With a wide range of functions and individual customization options, PEAKTOURe controls your automatic cutting process precisely, efficiently and in a material-saving manner.

The Fakuma trade show in Friedrichshafen is one of the most important events in the industry and we look forward to welcoming you in hall A6|booth A6-6111 to present our innovations and solutions.

See you soon in Friedrichshafen!

HI Tech & Industry Scandinavia from 03. - 05.October 2023

We will be exhibiting in Denmark for the first time! Together with PMH Systems, the Danish partner of Aristo Cutting Solutions, we will be present at the HI Tech & Industry Scandinavia. This is Scandinavia's leading technology and industry trade fair, celebrating its 60th anniversary this year.

📅 When: 03 to 05 Oct

🏢 Where: MCH Messecenter in Herning, Denmark

The HI show is the opportunity to see our latest technologies and solutions for automatic cutting. Gerald Meister will be on site together with colleagues from PMH Systems to answer your questions and provide insights into our innovative products.

If you have the chance to visit the fair, come by and meet us. We look forward to seeing you.

Simac Tanning Tech from 19th - 21st September 2023

RG Technologies will again be present at this year's Simac Tanning Tech. The fair will take place from September 19-21 in Milan.

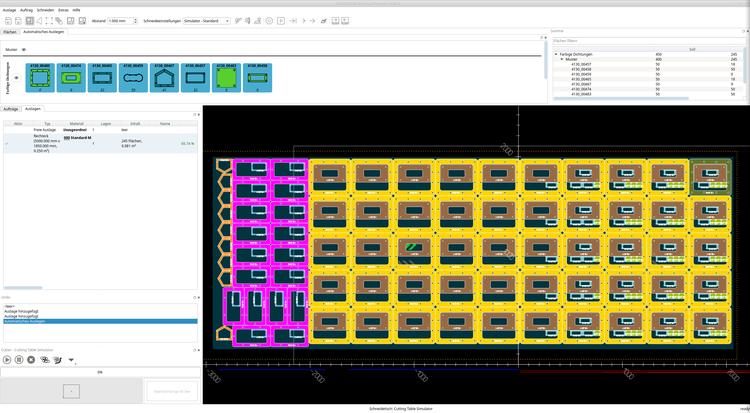

Together with our partner Aristo Cutting Solutions we will be presenting PEAKTOURe our innovative and powerful software and cutting solutions for efficient material and energy-saving processing of flat materials such as leather, textiles and composites.

In addition to PEAKTOURe produce, we will also be showcasing PEAKTOURe 3D for the technical flattening of 3D objects.

Visit us in hall 14 booth B30 and let us convince you of our products. We are looking forward to meeting you.

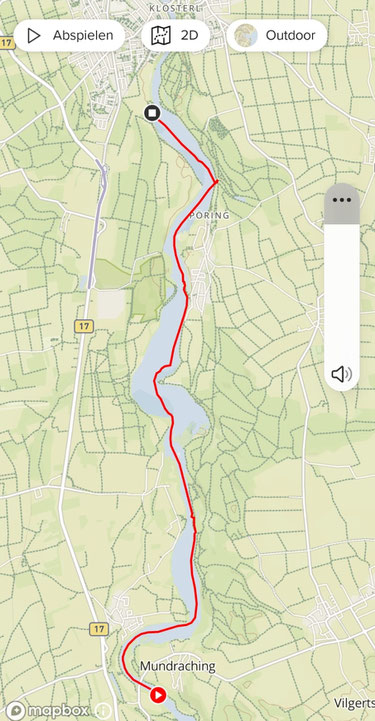

Impressions of our Team Day 2023

All year long we think about how we like to spend our traditional team day. This year we were once again drawn to the water, more precisely to the river Lech. Here the way was the goal. We travelled the route from Mundraching to Landsberg am Lech using canoes. On the total distance of 12 km two barrages had to be passed. Everyone arrived at the destination save and dry.

After a short hike through Landsberg from the Wildpark up to the Bayertor, we ended the eventful day with a culinary and Bavarian meal at the Metzgerwirt in Hurlach.

This successful team day will remain in our memories for a long time.

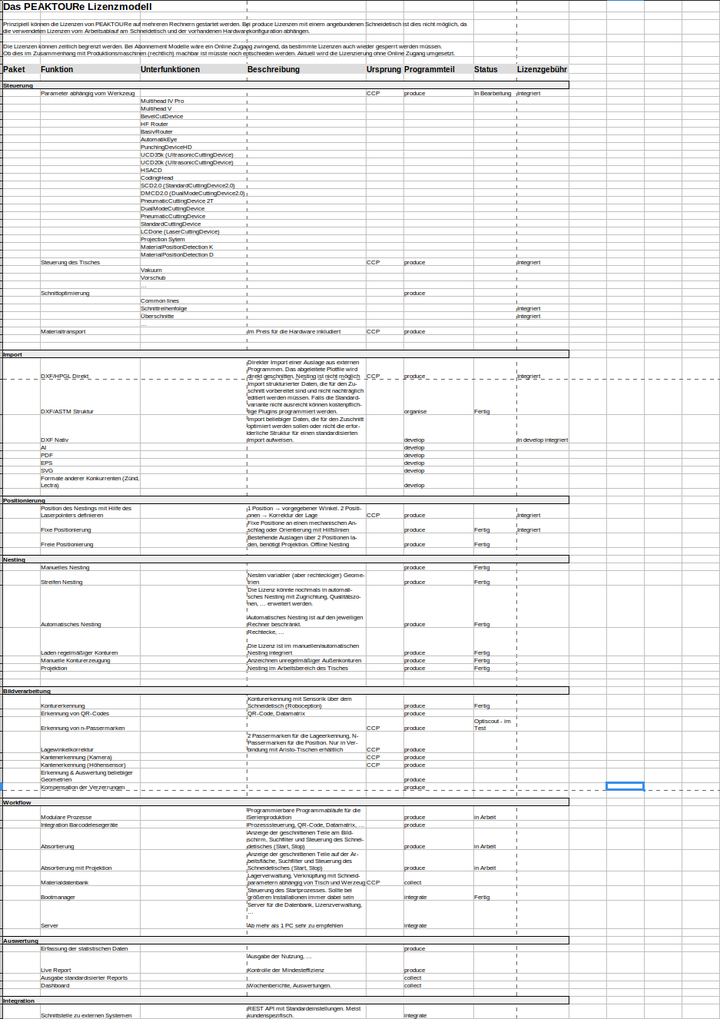

Developers Diaries #22 - Save Costs with the Perfect Licensing Model

Do you know the scenario, that you want to buy a car and do not attach great importance to chichi, but there is a certain function that is important to you? Do you perhaps prefer to forego this one functionality because you have to choose a higher engine, a different model variant and also some optional extras that are not relevant for you and these increase the price by far?

Do you open the latest word processing software from any provider and wonder who needs this multitude of (new) features that don't necessarily make your user interface any clearer? The fact is that 90% of users only use about 10% of the available functions.

In order to protect you from this cost and overload trap, we set a very high priority on the individual configurability of your personal software version during the development of PEAKTOURe produce. This does not only include the editing of the user interface, we understand this as standard. We start one step before and adapt the software to your requirements with the help of our license model. You determine the functions you need and receive an individual license package that is exactly tailored to your wishes.

Figure 1: License model, for you temporarily still fuzzy and as an Excel list

This customization of the software can even be extended to specific workstations.

- You want to nest on the screen? Then of course you do not need a license for projection.

- You only want to load and cut the already nested parts at the cutting table? Then the license for both automatic and manual nesting is not required for this workstation.

- You want to capture contours at a specific workstation? Here, too, the nesting license can be omitted, among other things.

Figure 2: UI von PEAKTOURe produce

The combinations of the individual licenses are already preconfigured by us for some industries. We will be happy to help you find the best solution for you, based on these specifications.

Stay online and best regards

Gerald Meister

Read all published blogs in the archive.

Das Team von RG Technologies freut sich auf Ihre Anfrage. Nehmen Sie am besten noch heute Kontakt mit uns auf.